When selecting the cassava processing machine,you must understand these before the inquiry

When many customers contact us for our cassava processing machine, they often ask same question first, how much is this equipment? What is the lowest price? The price issue usually the most concerned issues for many customers, but customers should understand that regardless of whether the price of the equipment is high or low, only the one that suits you is the best. So what kind of cassava processing equipment is suitable? Below Doing Company will analyze for you:

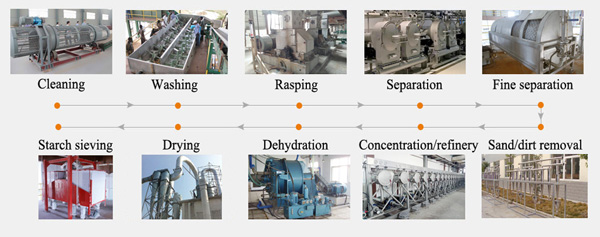

Cassava starch processing machines from Doing Company

Cassava starch processing machines from Doing Company

1. Your actual production needs and preliminary budget and investment

At the beginning of start cassava processing business, many people who have no relevant experience or have previously engaged in manual cassava processing must conduct market research in advance to understand and gradually determine the location of the plant, the planning and construction of the plant, the equipment footprint, and the source of processing materials, key issues such as sales channels and development of investment funds.

Cassava processing machine loading and delivery from Doing factory

Cassava processing machine loading and delivery from Doing factory

Finally, when purchasing cassava processing equipment, the consumer object (market) and product specifications (high quality, medium) are determined according to the development intention of your company, thereby determining the type of equipment or line required or the machine configuration, which is fully automatic production line, the quality production line, the simple production line or just a few separate cassava processing machines.

The prices of different sizes of cassava processing machines vary naturally, and the quality of finished cassava products (starch, flour, garri, dry chips) will vary. High-priced and high-quality cassava processing equipment has high automation, low energy consumption, high output and stable performance. The processed cassava products have good quality, fast profit and high profit. The small and medium-sized cassava processing equipment is simple in operation, small in investment and more suitable for budget lower customers. You need to choose the right cassava processing machine according to your own budget.

Cassava starch machine-centrifuge sieve

Cassava starch machine-centrifuge sieve

2. Processing capacity, produced cassava product type

The processing capacity of different customers and the type of finished cassava products are also two points that must be referenced when selecting equipment. Doing's cassava processing machines are mainly divided into cassava starch processing machine, cassava flour processing machine, garri processing machine, and dry cassava chips processing machine. Among them, the processing technology of starch is complicated, the requirements on the machine are high, so the price is naturally high.

Doing Company chooses the cassava processing machine according to the customer's processing capacity and the type of finished cassava product. Therefore, when selecting the equipment, you should inform us your daily processing capacity and the production plan, so that our sale manager can introduce you and match the right machine for you, then you can get the equipment quotation.

Cassava processing plant project

Cassava processing plant project

3. Production line configuration affects the price

Different types of cassava processing machines have different production line configurations, and the price difference is also relatively large. The same is used to process tapioca starch, the configuration is different, the processing quality, service life of the machine, and the quality of the finished starch are significantly different.

The machine is equipped with high quality, the quality of the finished product is stable and the quality is good; the machine is more energy-saving and cost-effective. The low configuration cassava processing machine has less investment and the product quality is not as stable as the high configuration.

In short, there are many suppliers of cassava processing machines in the world, and there are many types of equipment available, so there are many types to choose from. Different cassava processing machines have high and low prices, each with its own advantages and disadvantages. It requires customers to make rational choices based on individual circumstances and make appropriate choice.

As a professional manufacturer of cassava processing equipment, Henan Doing Company always focuses on the production needs of each customer and develops appropriate equipment selection solutions to help customers obtain good economic benefits.

Leave a message about When selecting the cassava processing machine,you must understand these before the inquiry

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I Just learning

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Others

- 2. What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Others

- 3.What is your capacity plan?

- Small scale garri machine

- 1ton per day

- 2tons per day

- 3tons per day

- 10tons per day

- 20tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- Middle type

- Large scale

- What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others